Qingdao Tent Machinery Co., Ltd. specializes in manufacturing plastic extrusion equipment production line. Trent machinery has standardized equipment production line. It is a professional plastic machinery manufacturer integrating scientific research, production, development and sales.

PP plastic honeycomb panel equipment is used to make all kinds of high-strength packaging boxes, such as logistics transportation turnover boxes, instead of traditional wooden boxes, trunk cover plate, trunk partition, trunk carpet base plate, side wall decorative plate, ceiling and other interior parts of passenger cars.

Characteristics of PP panel

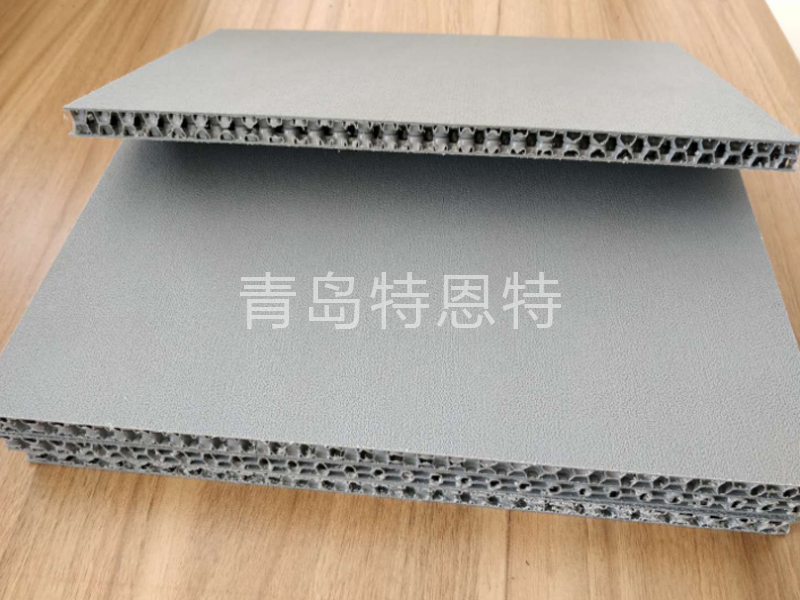

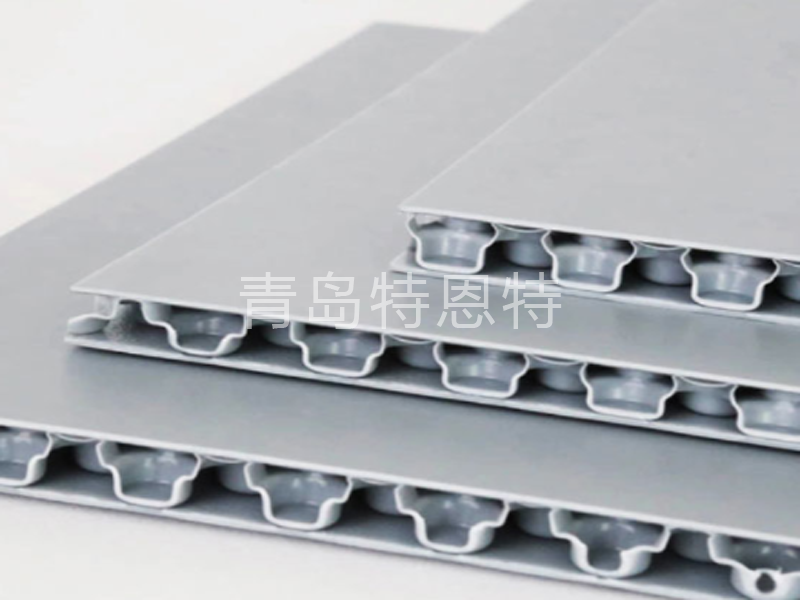

The production line adopts the one-time extrusion process and takes PP as the main raw material to produce three-layer sandwich plate. The two sides are thin surface layers and the middle is honeycomb structure, which can be layered single-layer plate and double-layer plate. PP honeycomb board can also be formed at one time, with double-sided cloth and film covering. It has the advantages of light weight, good stiffness, environmental protection, shock absorption and cold resistance, sound insulation, moisture-proof and heat insulation.